Quality Management Software for Dairy Production

Why Dairy Manufacturers Need a Robust Dairy QMS Solution

Superior quality and consumer safety are at the heart of dairy manufacturing. Consumers rely on dairy products for essential nutrition and expect them to be safe, wholesome, and free from contamination. Any compromise in quality, safety, or compliance can result in recalls, financial losses, and long-term damage to brand reputation.

To maintain high standards, dairy manufacturers must proactively manage risks such as microbial contamination, temperature fluctuations, chemical residues, and regulatory non-compliance. This is where a Quality Management System (QMS) purpose-built for the dairy industry becomes essential.

Implementing the best QMS software for dairy industry helps manufacturers ensure compliance, improve operational efficiency, and mitigate quality risks across the entire value chain.

Request a Free Demo

Trusted by Industry Leaders

How Does Dairy QMS Software Help Address These Challenges?

Leading dairy manufacturers are increasingly adopting QMS software to safeguard product quality, meet regulatory requirements, and streamline production processes.

An industry-specific dairy QMS System like QualityPro enables producers to stay in control of complex challenges and ensure consistent product excellence from raw milk to finished goods.

QualityPro empowers dairy teams to:

- Strengthen control over microbial, chemical, and temperature-related risks

- Streamline issue detection and resolution with standardized processes

- Enhance hygiene compliance and real-time documentation

- Ensure continuous audit readiness and regulatory alignment

It even integrates quality into daily operations, helping dairy manufacturers proactively manage risk, uphold safety standards, and deliver trusted, high-quality products—batch after batch.

Top Features of the Best QMS Software for Dairy Industry

Handle non-conformance issues like mislabelling, non-pasteurisation, poor sanitation & hygiene, packaging defects etc. efficiently. Find out root cause and take necessary corrective and preventive actions (CAPA).…Read More

Record, track, manage and resolve complaints related to various issues like quality, packaging, labelling, shelf-life and many more coming from various sources. Take complaint management full circle and enhance customer satisfaction...Read More

Identify learning gaps in areas like SOP adherence, regulatory compliance, and communication skills. Schedule targeted training for dairy plant staff, and track & store their progress for audits and future reference...Read More

Smoothly incorporate change within the organisation without disturbing day-to-day operations. Establish a proper workflow for documenting changes, update the concerned, review its impact and manage every step of the change control process...Read More

Manage organisational documents like procedures, licences, certificates, SOPs etc. Collaborate simultaneously on the same document version, enhancing teamwork; find docs using tags and even secure them with access rights...Read More

Identify and mitigate risks that impact milk and dairy product quality. Implement proactive quality management systems to drive continuous improvement and ensure compliance with food safety regulations…Read more

Ensure smooth internal and external audits with centralised storage of key compliance documents. Conduct timely audits focused on hygiene, food safety, and dairy quality standards to maintain regulatory compliance...Read More

Ensure precision of equipment like thermometer, pipettes, burettes, butyrometer, lactometer etc. used in dairy manufacturing. Schedule and track equipment calibration effortlessly to reduce risk of non-conformance and stay audit–ready all times...Read More

Make quality a habit with efficient inspection of dairy products. Set up quality control tests, organise inspection plans, manage results as alphanumeric, numeric, pass/fail, etc., and digitise various aspects of inspection process...Read More

Explore Benefits of QMS Software for Dairy Business

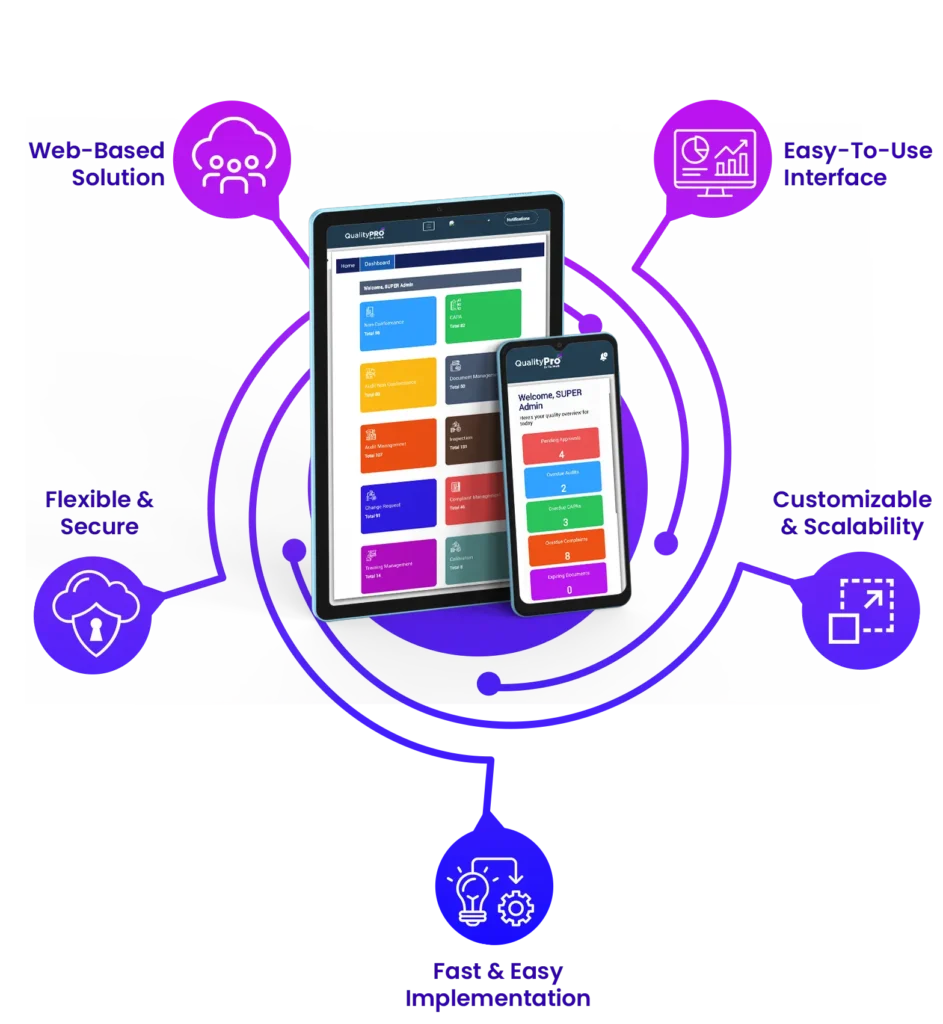

- User-Friendly Dairy QMS for Plant Teams : QualityPro’s intuitive interface is simple to navigate- even for dairy plant staff without technical backgrounds. From milk collection to final packaging, this dairy QMS system offers a simple, clean interface built for daily, hands-on operations.

- Web-Based QMS for Real-Time Dairy Production: Monitor quality checks at every stage — from milk reception to dispatch — with real-time, cloud-based access. This QMS for Dairy Industry ensures fast setup, collaborative workflows, and automated updates to keep your dairy unit aligned with FSSAI and global food safety standards.

- Customised QMS to Dairy Needs: Whether you’re recording batch-specific fat and SNF values, chilling centre data, or lab test results, QualityPro’s food quality management software in the dairy industry is built for flexibility.

- Fast Setup with Flexible Implementation: Choose between self-deployment or guided onboarding- whichever suits your dairy unit's pace and team capacity. Go live with minimal disruption.

- Dairy QMS System for All Business Sizes: Whether you're a local milk co-operative, a growing dairy brand, or a multi-unit dairy processor, this QMS for Dairy Production fits your scale- from 500 litres a day to lakhs.

- Scales as You Grow: As your dairy expands- new chilling centres, product lines, or export batches— this Dairy QMS software scales with you, ensuring consistency and control across locations.

- Secure and Reliable for Critical Dairy Data: Protects sensitive data like milk quality reports, vendor records, and compliance logs with enterprise-grade encryption, authenticated logins, and a 3-tier backup. QualityPro’s QMS software for dairy delivers peace of mind in a tightly regulated industry.

“Just one click, and you are one step closer to a transformation”

Know right away how QualityPro can transform your business

Frequently Asked Questions

A Quality Management System (QMS) for dairy industry is a structured framework that ensures every stage of dairy production- from milk collection to final packaging and delivery- meets consistent quality, safety, and regulatory standards.

In dairy, where product freshness, hygiene, and traceability are critical, a QMS helps standardize and digitise quality management processes, reduce risks, and improve overall efficiency.

By implementing a QMS, dairy producers can ensure that milk, cheese, yoghurt, butter, and other products reach consumers in the safest, freshest, and most compliant form possible. Ultimately, it safeguards brand reputation and consumer trust.

Dairy QMS software streamlines the audit process by digitizing and centralising all quality records, inspection reports, and compliance data at one secure platform. For dairy plants, this means auditors, internal or external, can easily access batch records, cleaning schedules, laboratory results, temperature logs and such with a few clicks.

The system automates audit checklists, sends reminders for upcoming inspections, and maintains a digital trail of corrective actions. This not only speeds up the audit process but also ensures that no documentation is misplaced or overlooked, making the process transparent and chaos-free.

The dairy sector must comply with strict food safety standards like FSSAI, HACCP, ISO 22000, and local dairy regulations. QMS software simplifies compliance by automating record-keeping, generating mandatory reports, and monitoring critical control points in real time. It ensures that pasteurisation temperatures, storage conditions, and microbiological test results are tracked and documented accurately.

Whenever a deviation occurs, the system flags it immediately so corrective actions can be taken before it becomes a compliance issue. This proactive approach prevents costly recalls and regulatory penalties.

When choosing a QMS for dairy facility, on must look for features like:

- HACCP and Food Safety Management – Monitor and document critical control points.

- Document Control – Maintain SOPs, training manuals, and certificates centrally, with anytime, anywhere access.

- Audit Management – Create, assign, review and implement audit checklists.

- Non-Conformance and CAPA Tracking – Record quality issues and follow up with corrective actions.

- Mobile Accessibility – Allow on-floor staff to log data in real time.

A cloud-based QMS for dairy producers gives dairy producers flexibility, speed, and scalability. By storing all quality data online, authorised teams can access it anytime, anywhere—whether it’s a production supervisor checking a pasteurisation log from the factory floor or a quality manager reviewing test results from another location.

Real-time updates mean faster decision-making, fewer delays, and quicker responses to quality issues. Additionally, cloud systems reduce the need for paper-based records, saving time and cutting administrative costs while ensuring that data is always backed up and secure.

Instant access to real-time data enables informed decisions, while alerts and notifications drive faster approvals, quicker innovation, and reduced wastage. Intuitive dashboards ensure deviations are caught early and no non-compliant products are released.