Quality Management Software for Steel Manufacturing Plants

Improve metallurgical consistency, optimise heat-treatment accuracy, and streamline NDT inspection workflows for defect-free steel output.

Role of QMS Software in Modern Steel Manufacturing

Steel is the backbone of modern infrastructure. From construction and transportation to machinery and tools, steel plays a crucial role in powering industries and economies. Its strength, durability, and versatility make it an indispensable material in everything from skyscrapers to surgical instruments.

With such wide-ranging applications, ensuring the quality of steel is absolutely important. Especially in sectors like construction, automotive, and energy, where the safety and longevity of end products depend heavily on steel’s performance, maintaining consistent quality standards becomes non-negotiable.

However, the steel manufacturing process is not without its challenges. It operates in high-temperature, energy-intensive environments that often result in machinery corrosion, asset wear, and operational inefficiencies. Additionally, the industry is among the largest contributors to industrial carbon emissions, putting immense pressure on companies to meet rising sustainability and environmental standards.

To tackle these complexities, it is essential for manufacturers to establish robust and compliant quality processes. Relying on traditional, paper-based quality management systems is no longer practical. These systems are time-consuming, error-prone, and incapable of delivering the speed, traceability, and data accuracy needed in today’s competitive steel market.

Adopting a digital Quality Management System (QMS) software for steel industry enables manufacturers to overcome these challenges effectively. From real-time monitoring and maintenance tracking to compliance management and workforce training, a digital QMS for steel manufacturing empowers organisations to improve product quality, ensure regulatory adherence, reduce downtime, and operate more sustainably.

In short, it lays the foundation for a stronger, more resilient steel manufacturing process.

Request a Free Demo

Trusted by Industry Leaders

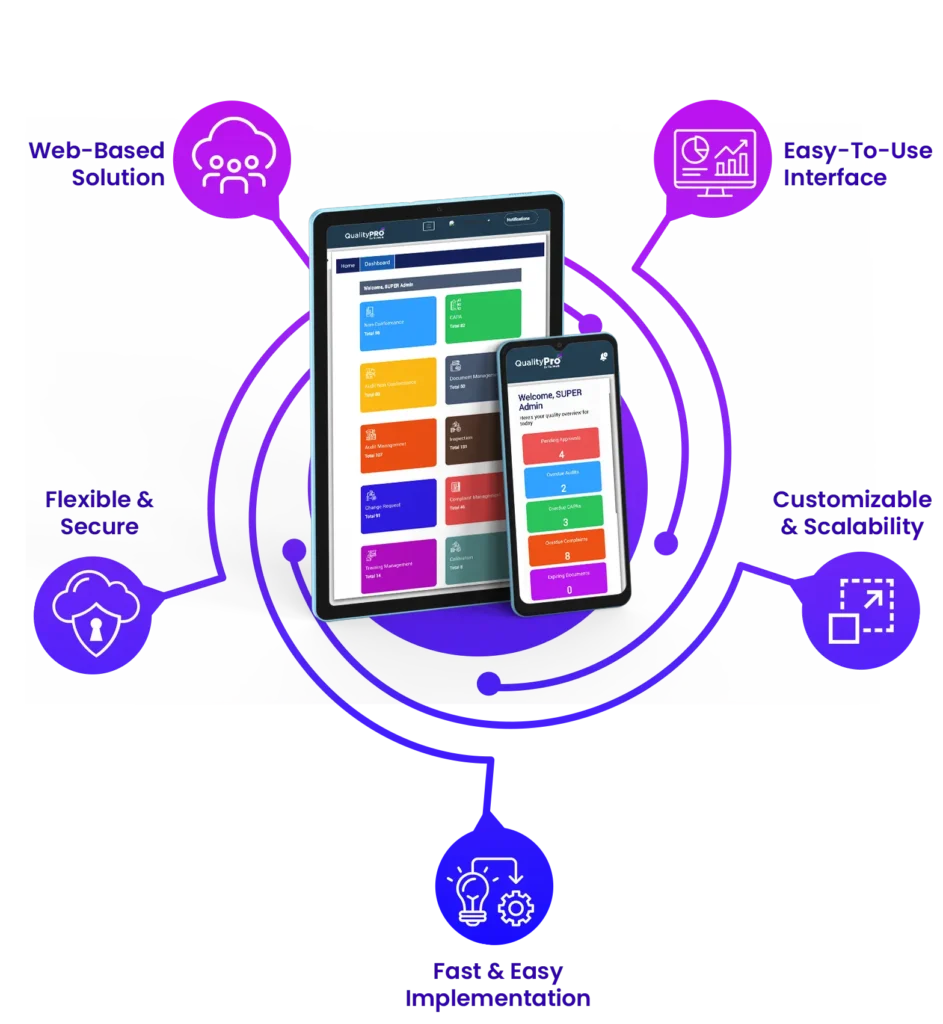

QualityPro—The Right Digital QMS for Steel Manufacturing

QualityPro is equipped with a lot of capabilities that’ll help steel manufacturers to not only digitise and protect documentation, but also make processes compliant, and eco-friendly.

This steel QMS software can help industry to flip the story of being the most pollution-causing industry after chemical industry, and can even contribute to reduce its carbon footprints.

It is a best-in-class eQMS software that enables companies to:

- Create, edit and manage various documents like production process flow chart, raw material test reports, quality control inspection reports, engineering drawing, SOPs etc.

- Create risk-based CAPA process

- Ensure employee adherence through standardised processes

- Manage full cycle of complaints- from complaint registration to resolution

- Fill the training gaps of employees with systematic plans and execution

- Ensure that machines and equipment measure and function correctly

A steel manufacturing QMS- like QualityPro- enables orgnaisations to uphold quality and strive for continuous improvement.

Key Features of Steel Manufacturing QMS Software

Efficiently handle, record and manage various NCs like operator errors, incorrect process parameters, incorrect hole size etc., and apply necessary CAPA effectively to prevent recurrence…Read More

Handle, record, track and control various complaints like scrap quality, iron ore quality, slag formation, dimensional inaccuracies, strength and durability issues etc. – from complaint punching to resolution effectively – ensuring continuous improvement...Read More

Automate training processes, create schedules, curriculum, and fill training gaps in employees. Track their knowledge regarding GXP, and other regulations to ensure processes are compliant and quality is intact...Read More

Establish structured change control management. Document, evaluate, review, and manage modifications in steel manufacturing process, ensure regulatory compliance and operational efficiency...Read More

Mange critical SOPs related to fabrication, welding, erection and so on to ensure regulatory compliance. Implement and tick-on–the go capability ensures that processes follow prescribed SOP. The system even stores records of a master SOP for future references...Read More

Create, store, edit, search, and manage various documents– like product lists, land documents, cross-section plans, fabrication drawings, etc.- of steel plant seamlessly. Enable real-time collaboration of different users on same document for improved productivity...Read More

Identify and mitigate risks affecting product quality. Implement proactive steps to drive continuous improvement and ensure regulatory compliance…Read more

Carry out internal and external audits seamlessly with centralised repository of documents. Conduct timely regulatory, GxP audits to maintain industry standards. ...Read More

Seamlessly calibrate machines and equipment to generate correct results. Set calibration frequency to ensure it generates results that fulfills the organisation’s passing criteria...Read More

Carry out inspections minutely to ensure that they are duly documented. Custom design inspection rules, values and threshold to suit your organisation’s standards...Read More

Exceptional Benefits of Implementing QMS in Steel Industry

- Enhanced Business Processes – Optimised workflows and tailored interfaces improve efficiency.

- Regulatory Compliance – Ensures adherence to various quality standards.

- Improved Quality Control – Real-time monitoring for swift issue resolution.

- Customer Satisfaction – QMS for steel provides a structured complaint resolution system.

- Cost Savings – Reduces rework by identifying quality issues early.

- Customer Growth & Retention – Maintains consistent product quality, attracting new customers.

- Competitive Advantage – Demonstrates a commitment to quality management in the steel industry.

- Data-Driven Decision-Making – Enables informed decision-making through comprehensive analytics.

- Employee Engagement – Fosters a culture of quality management and accountability.

“Just one click, and you are one step closer to a transformation”

Know right away how QualityPro can transform your business

Frequently Asked Questions

A Steel Quality Management System standardises every stage of the production process—from raw material inspection to final product testing. It ensures that specifications are consistently met, non-conformities are flagged early, and corrective actions are documented. This results in fewer defects, enhanced traceability, and customer confidence in quality.

Absolutely. Heat number tracking is essential in steel manufacturing for material traceability. Our QMS system for steel plant ensures complete batch tracking from source to shipment, allowing you to retrieve the full production history of any coil, bar, or sheet with a single click.

Our steel QMS software integrates with inspection checkpoints on the shop floor to capture real-time data during each process stage– rolling, cutting, welding, or galvanising. Quality parameters can be set for each line, and alerts are triggered if any reading goes beyond acceptable tolerance levels.

You’ll have access to custom dashboards, defect trends, rejection analysis, supplier quality performance, and audit scores. These insights help drive continuous improvement, reduce wastage, and make data-driven decisions.

About Us

QualityPro is an eQMS software by TecWork Global Business Solutions, specially tailored for industries such as Electronics, Manufacturing, Electric Vehicles, Automotive, Food and Beverages, Solar panels, Pipe, Steel and more. TecWork Global Business Solutions, the parent company, endeavours to converge cutting-edge technology with business excellence. At TecWork, we are dedicated to empowering businesses through innovative solutions that specialise in and seamlessly align with diverse business objectives such as fleet management software, field force management software, and others.