QMS Software for Consumer Goods Industry

Improve product consistency, accelerate market release, ensure packaging and regulatory compliance with a unified Consumer Goods QMS Software.

What are the Major Quality Challenges in FMCG industry?

Quality is of paramount concern for the Fast-Moving Consumer Goods (FMCG) industry due to its direct impact on consumer safety and satisfaction. Every day, millions of consumers in a vast market consume FMCG products, such as food, beverages, personal care items, and other consumer goods. Any compromise in quality can result in health risks, product recalls, reputational damage, and a loss of consumer trust.

Maintaining consistently high quality is not only a regulatory requirement but also essential for brand reputation, customer loyalty, and long-term success in this highly competitive industry. To achieve this, consumer goods companies should implement FMCG Quality Management Software.

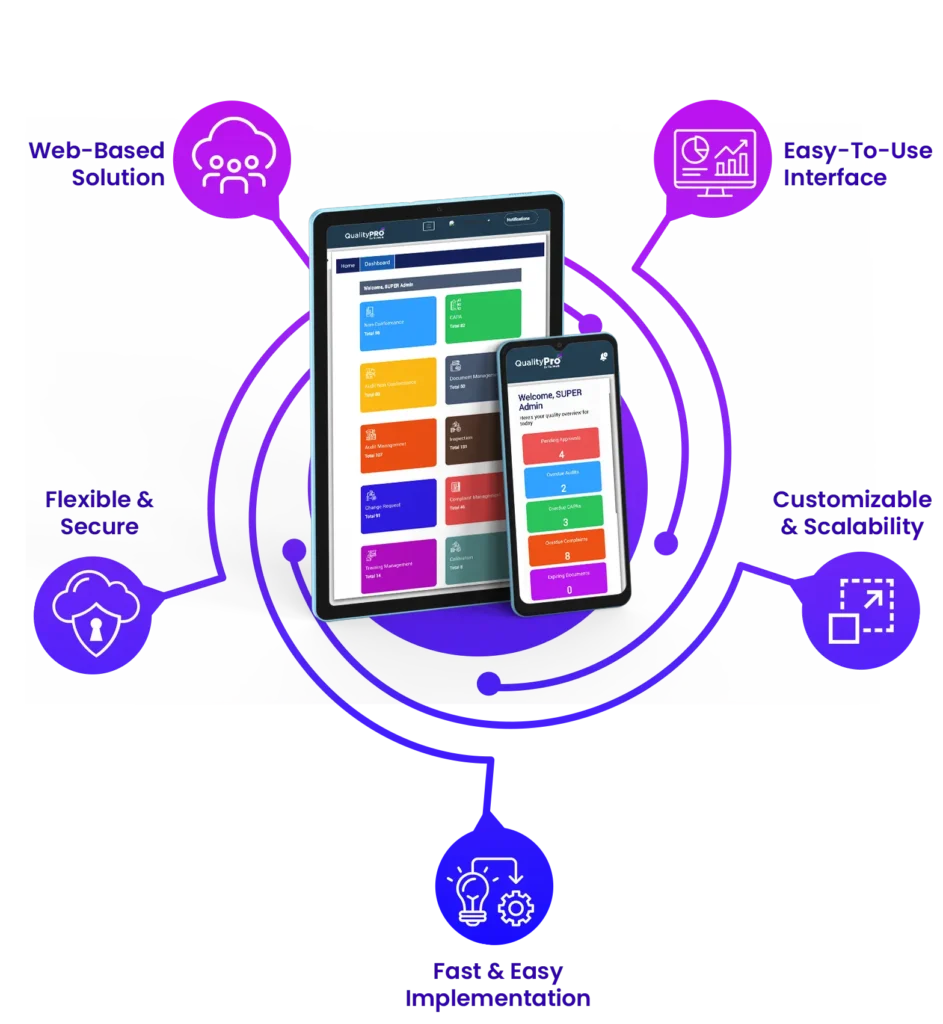

QualityPro is a Quality Management System for Consumer Goods Industry designed to make quality management easier. It empowers the consumer goods industry to enhance product and process quality, reducing waste and customer complaints. This improves market share by mitigating operational and compliance risks.

Request a Free Demo

Trusted by Industry Leaders

A Closer Look at QMS for Consumer Package Goods Industry

This QMS for FMCG products seamlessly automates important quality operations, such as Document Management, Audit Management, NC/CAPA Management, Training Management, and much more.

It efficiently manages non-conformities, tracks customer complaints, standardises documents, streamlines training, accelerates audits, and ensures compliance, addressing essential aspects of the quality management system. It helps in organising and overseeing quality-related records, workflows, and processes in a structured manner.

Additionally, QMS for Consumer Goods enhances quality processes, captures real-time data, and fosters seamless team collaboration, making it the ultimate solution to enhance product quality, reduce recalls, and earn customer trust in the FMCG industry.

Features of Quality Management Software for FMCG Industry

Efficiently handle non-conformance (NC) issues like deviation from established procedures, shortcomings in programme implementation, etc. Perform root cause analysis and apply corrective actions to avoid prevent recurrence…Read More

Effectively deal with complaints like inappropriate execution of the plan, gaps in communication, etc. Track the status and resolution of such complaints to establish positive relationships with stakeholders...Read More

Identify the learning gaps like procedural knowledge, legal requirements knowledge, communication lacunae etc. and schedule trainings for employees. Track and store the training progress of staff for future reference...Read More

Smoothly incorporate change in the organisation without disturbing day-to-day operations. Establish a proper workflow for documenting changes, update the concerned, review their impact and manage every step of the change control process...Read More

Manage organisational documents like procedures, certificates, SOPs, fundraising documents etc. Collaborate simultaneously on the same document version, enhancing teamwork...Read More

Manage various risks like financial risk, cybersecurity risk, operational risk, governance risk, etc., associated with FMCG organisation. Mitigate probable risks and drive continuous improvement across the organisation…Read More

Make the organisations audit-ready, be it internal or external, by ensuring compliance with various regulations. Conduct mock audits and find the gaps to fill during real audits and prevent penalties and reputational dents...Read More

Benefits of Quality Management System for Consumer Goods

- Personalised cockpits to improve operational effectiveness

- Compliance with industry standards

- Better overall control through regular alerts tasks & approvals

- Address customer complaints easily

- Foster a culture of continuous improvement

- Savings on rework, time, and resources

- Better manageability in producing highly perishable i.e., fast-moving goods

- Growth in new customers, and increased retention by improving customer satisfaction

- Improved decision-making process

- Increased employee engagement

“Just one click, and you are one step closer to a transformation”

Know right away how QualityPro can transform your business

Frequently Asked Questions

A Quality Management System (QMS) for Fast-Moving Consumer Goods (FMCG) industry is a comprehensive framework designed to uphold product quality, ensure regulatory compliance, and enhance operational efficiency. Within this high-volume, fast-paced environment, a QMS facilitates robust document control, audit readiness, non-conformance management, customer complaint resolution, and training compliance.

Leveraging quality management software for the FMCG industry mitigates quality risks, safeguards brand reputation, and ensures consistent delivery of goods that meet both consumer expectations and statutory standards, thereby boosting market competitiveness.

A QMS software for consumer goods industry empowers businesses to swiftly detect, document, and minimise non-conformances across the supply chain. By streamlining Corrective and Preventive Actions (CAPA) and integrating with root cause analysis tools, the system enables the identification of systemic issues and curbs their recurrence.

This is particularly vital for avoiding product recalls, maintaining regulatory compliance with bodies, and ensuring operational excellence in the consumer-packaged goods landscape.

Absolutely. A QMS software for consumer goods, just like QualityPro, offers a systematic approach to customer complaint management by logging incidents, enabling traceability, and conducting in-depth investigations to determine root causes.

Whether the issue pertains to packaging errors, or any other, QualityPro ensures swift resolution and feedback loops. This structured handling strengthens brand equity, enhances consumer trust, and ensures adherence to retailer specifications and regulatory benchmarks.

An effective QMS for CPG industry incorporates an integrated training management module. This module identifies skill gaps, facilitates the scheduling of Good Manufacturing Practices (GMP) and HACCP training, and tracks employee certification status.

It ensures that personnel are continuously aligned with quality protocols, regulatory standards, and Standard Operating Procedures (SOPs), fostering a culture of compliance, accountability, and continuous improvement across production lines and quality control departments.

A QMS system for consumer goods features a centralised document management system (DMS), enabling businesses to efficiently manage essential documents such as SOPs, audit checklists, supplier quality agreements, and material specifications.

The software ensures version control, secure access, and real-time updates, improving team collaboration and audit preparedness. This is critical for maintaining consistency in manufacturing processes and demonstrating compliance during regulatory inspections.

Yes, a QMS system for consumer goods streamlines both internal and external audit management through automation and scheduling tools. It facilitates compliance tracking, gap analysis, and the implementation of corrective actions, ensuring organisations remain audit-ready year-round.

The system also supports adherence to global regulations which are pivotal in securing retailer partnerships and ensuring food safety in the supply chain.

A QMS for the FMCG industry delivers substantial operational and quality advantages, including:

- Real-time dashboards for actionable insights and decision-making.

- Assured compliance with FMCG industry standards and regulatory frameworks.

- Enhanced workflow automation, reducing manual errors and inefficiencies.

- Robust non-conformance tracking to prevent repetitive quality issues.

- Streamlined customer complaint resolution, improving consumer satisfaction and loyalty.

- Comprehensive document control, aiding in traceability and regulatory audits.

- Proactive risk management, reducing potential disruptions in the supply chain.

- Effective training and competency tracking, ensuring a skilled and compliant workforce.

- Reduced incidence of product recalls, rework, and material wastage, preserving margin and brand integrity.

About Us

QualityPro is an eQMS software by TecWork Global Business Solutions, specially tailored for industries such as Electronics, Manufacturing, Electric Vehicles, Automotive, Food and Beverages, Solar panels, Pipe, Steel and more. TecWork Global Business Solutions, the parent company, endeavours to converge cutting-edge technology with business excellence. At TecWork, we are dedicated to empowering businesses through innovative solutions that specialise in and seamlessly align with diverse business objectives such as fleet management software, field force management software, and others.