Quality Management Software for Pipe Manufacturing Industry

Enhance weld strength, minimise dimensional variations, and maintain full batch traceability for high-performance pipe manufacturing QMS Software.

Challenges of Pipe Manufacturing Without Quality Management Software

With the rise in urban development, this industry is adopting advanced technologies like IoT-enabled pipelines and eco-friendly, sustainable materials. However, the basic challenges like maintaining pipeline quality, corrosion control, changing raw material costs, and the need to comply with strict quality standards still persist. Of these, quality is one of the major aspects that cannot be left to chance.

As pipelines transport vital resources over great distances (thousands of miles), even minor quality issues can cause serious problems, including leaks, environmental dangers, safety concerns, costly repairs, and legal penalties. Without a solid QMS for Pipe Manufacturing, pipe producers encounter several difficulties.

- Difficulty complying with standards like API 5L, ISO 9001, or ASME codes

- Higher rework and rejection rates from undetected non-conformities

- Scattered inspection records that slow down audits

- Unorganised certificates and intensive paperwork

- Delayed response to quality issues due to manual or disconnected systems

- Untracked process deviations that impact long-term pipeline performance

- Inconsistent pipe quality due to welding flaws, surface cracks, or improper heat treatment

Request a Free Demo

Trusted by Industry Leaders

Trusted QMS Software for Pipe and Pipeline Manufacturers

QualityPro is a web-based QMS Software for Pipe manufacturing designed specifically for pipe manufacturers to help digitise quality workflows, ensure compliance, reduce risks, and maintain top-tier quality at every stage.

With seamlessly integrated modules, QualityPro improves internal coordination and enhances transparency across departments. It automates document control, simplifies regulatory compliance, systematises audit and training schedules, and ensures process consistency by generating and managing SOPs with ease.

The software also secures critical data like weld certifications, inspection results, and material traceability records, while minimising manual errors through automation. Its user-friendly dashboard lets you create shortcuts to key documents, tasks, quality checks, and ongoing projects, helping teams stay on top of every detail.

QualityPro’s personalised “QMS Cockpit” acts as your central command center—letting you access documents, manage tasks, handle alerts and notifications, and much more, all in just a few clicks.

Whether you're manufacturing pipelines for oil, gas, water, or industrial use, QualityPro empowers your team to build safer, stronger, and more reliable pipeline systems and is one of the most trusted QMS Software for Pipeline Industry.

Key Modules of QMS Software for Pipes and Tubes Industry

Address non-conformance (NC) issues like welding flaws, misaligned pipe joints, or coating imperfections that don’t meet industry specifications. It enables complete tracking of non-conformances, root cause analysis, corrective/preventive action planning, task assignment, approvals, verification, and closure. It ensures compliance, accountability, and continuous quality improvement through a centralised, audit-ready system…Read More

Address complaints such as pipe leakage, delayed delivery, corrosion problems, or installation errors. Capture, categorise, and track customer complaints from initiation to resolution. This streamlines investigation, root cause analysis, and response, ensuring timely closures, customer satisfaction, and regulatory compliance...Read More

Identify skill gaps such as pipeline fabrication, safety compliance (e.g., ASME/ISO), inspection procedures, etc. Schedule and monitor training programs, review performance, find the best fit for a job/task, and maintain a verified audit trail of staff qualifications and certifications...Read More

Manage and record all changes be it in materials, designs, or production steps with clear version tracking. Get real-time alerts on who made or viewed changes, and keep all departments informed to ensure smooth implementation and zero confusion. Schedule training for the change and reaccess proper implementation of the change...Read More

Securely store and organise crucial documents such as engineering drawings, quality plans, SOPs, test certificates, and inspection logs. Maintain full version control and provide secured access without compromise. Collaboratively work on the same document, search them through tags and maintain master SOPs along with their records...Read More

Track and prioritise risks such as weld cracks, coating defects, supply chain delays, or non-compliance with pressure standards. Generate risk heat maps, assign controls, and keep registers updated for ongoing mitigation…Read more

Plan, schedule and carry out audits focused on production quality, regulatory standards (API, ISO, etc.), and internal compliance. Record findings, track corrective actions, and maintain full transparency for internal teams and external auditors. Run mock audits when needed to stay prepared ahead of official inspections...Read More

Ensure all equipment—like ultrasonic testers, pressure gauges, and weld inspection tools—remain calibrated accurately. Schedule calibrations, maintain traceable logs, and receive alerts to stay audit-ready and ensure measurement accuracy...Read More

Design inspection plans for pipe segments, joints, coatings, and welds. Define inspections, associate them with processes and products, log test results as alphanumeric/numeric/pass/fail, flag non-conformities, and apply multi-level approvals to ensure each product meets strict quality and compliance benchmarks...Read More

Digitally manage and standardise all Standard Operating Procedures — from pipeline fabrication, welding, and coating to final inspection and commissioning — ensuring every process follows approved, up-to-date instructions.

Top Reasons to Choose QualityPro Pipe Industry QMS Software

Implementing the QualityPro QMS solution benefits the Pipeline Manufacturing Industry in numerous ways-

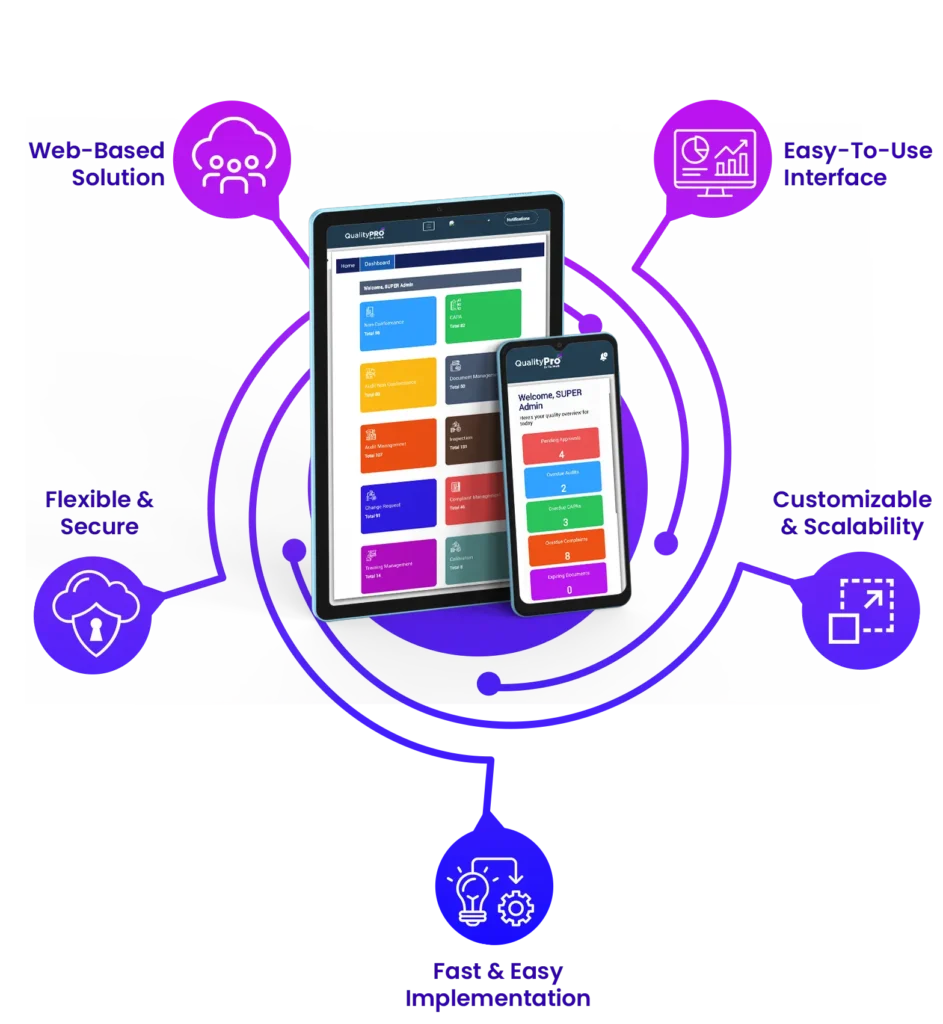

- Easy-to-use Interface: Navigating the user-friendly interface of QualityPro QMS doesn't require technical expertise. It’s easy. It’s clear. It’s intuitive.

- Web-Based Solution: Besides ensuring low-cost implementation, the web-based version offers accessibility, collaboration, and real-time tracking of quality-related activities. Moreover, automated updates keep businesses in line with the latest norms.

- Customisable Fields: Thoughtfully built to meet unique data needs, QualityPro Pipe QMS offers customisation of fields as per the company’s policy.

- Fast and easy Implementation: QualityPro provides the flexibility of dual implementation modes—Self and Vendor Guided—allowing users to choose according to their preferences.

- Any Business Size: Caters to the requirements of companies of any size, including small startups, medium and large enterprises belonging to any industry- process or discrete manufacturing, non-profits, automotive, electronics, and more.

- Scalability: Effortlessly meet the needs incepted by the growth of your organisation as QualityPro QMS for pipe manufacturing can scale as you grow and expand.

- Flexible and Secure:Completely secured with authenticated logins, encrypted data, best-of-breed security systems, 3-tier backup, and recovery plan, etc., so that you are at peace, always!

“Just one click, and you are one step closer to a transformation”

Know right away how QualityPro can transform your business

Frequently Asked Questions

A Quality Management System (QMS) for the pipeline industry is a comprehensive framework designed to ensure safety, integrity, and compliance across pipeline design, fabrication, welding, testing, and maintenance. It aligns operations with international standards such as ISO 9001, API Q1/Q2, and ASME B31, ensuring every joint, weld, and material used meets stringent quality benchmarks.

A robust QMS enables pipeline companies to maintain traceability, reduce risks of leaks or ruptures, and guarantee safe, reliable energy transportation.

Pipelines operate under extreme pressures, temperatures, and environmental conditions — where even a minor defect can lead to catastrophic failure, environmental hazards, and regulatory penalties. Quality in this sector is not optional; it’s critical for public safety, operational reliability, and environmental protection.

A QMS ensures each stage of production and installation — from raw material inspection to hydrostatic testing — adheres to strict standards, preventing failures before they occur.

Pipeline manufacturers and operators often face challenges such as:

Inconsistent welding quality and lack of traceability in weld records.

Manual inspection errors and incomplete documentation.

Difficulty in managing supplier quality for pipes, coatings, and fittings.

Complex compliance requirements from multiple authorities (ISO, API, ASTM, OSHA).

Reactive maintenance and delayed corrective actions after failures.

An integrated pipeline QMS software eliminates these challenges by automating inspections, centralising documentation, and ensuring full visibility across the pipeline lifecycle.

QMS software streamlines and digitises critical quality workflows — from NDT inspections, material traceability, and pressure testing, to welding procedure qualification and calibration management.

It ensures real-time monitoring of process parameters, enabling early detection of non-conformities. This results in fewer reworks, higher compliance rates, and enhanced operational safety. Additionally, it simplifies audit readiness by maintaining a single source of truth for all quality data.

Compliance with international standards such as API, ISO, ASME, and DNV is mandatory for pipeline projects. A QMS ensures that every component and process — from pipe mills to installation sites — follows documented procedures and is backed by verifiable quality evidence.

Through digital records, audit trails, and automated workflows, it guarantees traceability, accountability, and safety assurance across the entire pipeline network.

QualityPro is purpose-built for high-risk, high-regulation sectors like pipeline manufacturing and operation. It brings together process control, inspection management, CAPA, and compliance automation in one platform.

With its intuitive interface, cloud scalability, and deep integration with ERP systems, QualityPro enables teams to monitor weld quality, manage inspections, and ensure zero-compromise compliance effortlessly.

Trusted by leading engineering and energy firms, QualityPro delivers unmatched reliability, safety, and efficiency — helping you maintain the integrity of every pipeline you build or manage.

About Us

QualityPro is an eQMS software by TecWork Global Business Solutions, specially tailored for industries such as Electronics, Manufacturing, Electric Vehicles, Automotive, Food and Beverages, Solar panels, Pipe, Steel and more. TecWork Global Business Solutions, the parent company, endeavours to converge cutting-edge technology with business excellence. At TecWork, we are dedicated to empowering businesses through innovative solutions that specialise in and seamlessly align with diverse business objectives such as fleet management software, field force management software, and others.