Quality Management Software for Oil and Gas Industry

Trengthen ISO compliance, reduce operational risks, and maintain asset-quality traceability with an Oil and Gas-ready QMS solution.

Major Quality Management Challenges in Oil and Gas Industry

Traditionally, the oil and gas industry has fuelled human development and advancement. The industry, being absolutely volatile and susceptible to major risks, is highly regulated. Besides, the industry can cause serious environmental impacts and therefore confines itself within the boundaries of stringent regulations.

Although these laws and regulations are helpful for the ecological balance of the planet, the same are nightmares for oil and gas business owners. Even a slight ignorance can cause them huge penalties, not only monetarily but also in relation to their brand image.

Additionally, inconsistent documentation, scattered quality records, and manual error-prone processes increase operational vulnerabilities. Ensuring traceability for every sample, audit, or inspection becomes a daily struggle.

Frequent equipment failures, supplier variations, and unpredictable plant conditions further add to the complexity. The constant need to demonstrate compliance during audits keeps teams under pressure, leaving very little room for oversight. These and many more challenges constantly make organisations hunt for a better ally to take care of their concerns, preferably a QMS in Oil & Gas Industry.

Thankfully, they have a reliable solution by their side. They have QualityPro.

Request a Free Demo

Trusted by Industry Leaders

How Does QMS Software Help the Oil and Gas Industry Face Challenges?

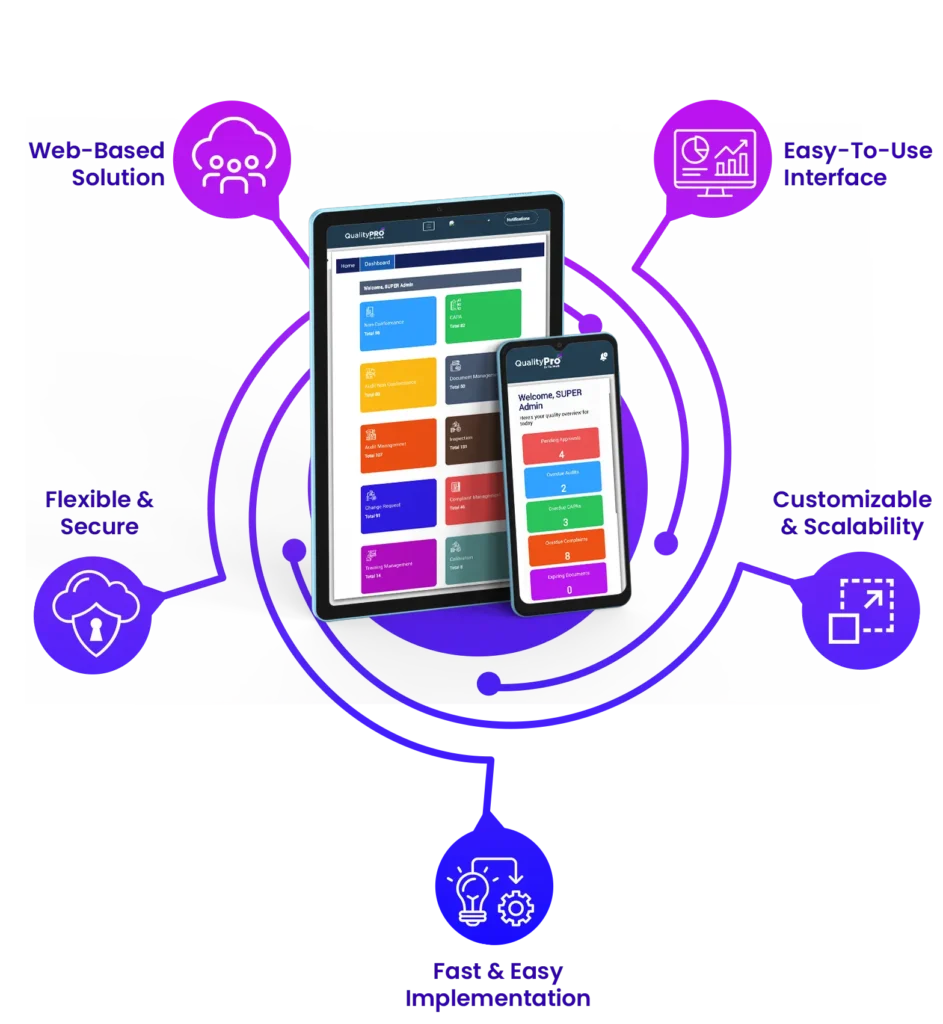

QualityPro is a web-based eQMS for oil and gas industry which helps these industry players to mitigate risks, meet compliance and oversee various quality management processes and procedures to find out gaps for improvement.

This quality management system for petroleum, petrochemical and natural gas industries ensure steady product quality by helping organisations to align with industry best practices defined in Quality Standards such as ISO 9001:2015.

QualityPro is equipped with various interconnected modules. These modules enhance internal communication and ensure seamless and real-time dissemination of information throughout the system.

With an array of these inter-connected modules organisations can manage documents, mitigate risks, adhere to compliance, foster training among the teams, perform audits and advance towards continuous improvement.

Being ISO/TS 29001 compliant QMS for oil and gas industry, it reduces errors by automating various quality management processes. Moreover, security and tagging of various crucial documents like exploration and production data, reserve estimates, JV agreements, production techniques, Health, Safety, and Environment (HSE data) etc. compliance is meticulously managed and ensured.

Additionally, this QMS software for oil and gas has personalised hub to control, manage and access various tasks, documents, alerts, notifications, and more in just few clicks. Various reports offer great visibility into performances of departments and set path for overall improvement.

Prominent Modules of QMS Software for Oil and Gas Industry

Address nonconformances such as equipment breakdowns, pipeline leaks, process deviations, or safety breaches in drilling, refining, or transport operations. Conduct detailed root cause analysis and apply corrective and preventive actions (CAPA) to prevent recurrence and ensure compliance with API, ISO 9001, and HSE standards.

Manage supplier, contractor, or customer complaints arising from fuel quality issues, delayed deliveries, or service noncompliance. Track, investigate, and resolve each case promptly to maintain credibility and meet contractual and regulatory expectations.

Identify training needs across rig operators, refinery technicians, safety officers, and field engineers. Schedule and track training on topics such as HSE protocols, hazard communication, confined space entry, and process safety management to build a skilled, safety-driven workforce.

Handle changes in drilling procedures, refinery processes, equipment configurations, or safety systems through a structured approval workflow. Assess risk, review impacts, and communicate updates across teams to ensure smooth and compliant transitions.

Control and maintain essential documents such as SOPs, maintenance logs, MSDS, inspection certificates, permits, and engineering drawings. Enable version control, secure access, and real-time collaboration for teams working across rigs, refineries, and offices.

Identify and mitigate risks related to process safety, asset integrity, environmental impact, and supply chain disruptions. Use proactive risk assessments to minimize incidents, enhance safety performance, and ensure business continuity across operations.

Ensure audit readiness for HSE, ISO, and regulatory audits by maintaining accurate records and evidence. Plan and conduct internal and supplier audits, track findings, implement CAPAs, and demonstrate compliance during regulatory inspections or client evaluations.

Digitally manage and standardise all Standard Operating Procedures across exploration, drilling, refining, and distribution processes. Ensure that field operators, engineers, and maintenance crews follow the most up-to-date and approved SOPs to maintain safety, operational consistency, and compliance with industry standards like API and ISO.

Plan, execute, and record inspections for pipelines, rigs, storage tanks, and refining equipment. Use digital checklists and real-time reporting to track inspection results, detect anomalies early, and ensure compliance with environmental, safety, and operational regulations.

Schedule and monitor calibration of critical instruments such as pressure gauges, flow meters, temperature sensors, and analyzers. Maintain precision in readings to ensure accurate process control, safety assurance, and compliance with international standards like ISO 9001, API Q1, and OSHA requirements.

Top Reasons to Choose QualityPro EQMS for the Oil and Gas Industry

Implementing QualityPro EQMS empowers oil and gas organisations to enhance safety, ensure regulatory compliance, and maintain consistent quality across exploration, production, refining, and distribution.

- All-in-One QMS Solution- A complete QMS platform that combines top-tier modules like Audit, Document, Inspection, Training, Calibration, Change, and Complaint Management in one centralized system.

- Easy-to-Use Interface - QualityPro’s intuitive, user-friendly interface makes it easy for field engineers, safety officers, and quality managers to manage incidents, deviations, and audits — no technical expertise required.

- Web-Based Solution - Access your QMS anytime, anywhere. The web-based platform enables real-time collaboration across drilling sites, refineries, and corporate offices, ensuring visibility and control over quality processes. Automated updates keep your system aligned with API, ISO, and HSE standards.

- Customisable Fields - Tailor QualityPro to your unique workflows — from equipment maintenance tracking and supplier evaluations to safety audits and process monitoring — all configured to match your organisation’s standards and policies.

- Fast and Easy Implementation - Choose between self or vendor-guided implementation for quick, seamless deployment without interrupting daily operations or ongoing site activities.

- For Any Business Size - Whether you’re an independent oilfield operator, service contractor, or global energy enterprise, QualityPro scales to fit your business model and operational complexity.

- Scalable and Secure- As your operations expand across new fields or regions, QualityPro scales effortlessly while ensuring data security, encrypted access, and multi-tier backup systems, giving you peace of mind and uninterrupted performance.

“Just one click, and you are one step closer to a transformation”

Know right away how QualityPro can transform your business

Frequently Asked Questions

A QMS is vital for oil and gas companies as it ensures compliance with regulatory frameworks, enhances asset integrity, minimises operational downtime, and upholds product and service quality. It supports alignment with standards like ISO 9001, and other sector-specific regulations, all while optimising performance and controlling costs in high-risk environments.

QualityPro QMS for oil and gas delivers robust process governance by enabling real-time data visibility, automating compliance workflows, and driving continuous quality improvement.

It supports audit trail management, version-controlled documentation, and systematic corrective and preventive actions (CAPA), crucial for maintaining operational excellence across exploration, production, refining, and distribution activities.

A Oil and Gas QMS enhances regulatory compliance by automating documentation, standardising compliance tracking, and generating audit-ready reports. It ensures alignment with critical standards and legislative requirements, including ISO, OSHA, and environmental regulations fostering a culture of accountability and compliance.

An effective QMS software solution for oil and gas industry includes the following key functionalities:

- Integrated audit management (internal and regulatory)

- Controlled document lifecycle and version management

- Risk and incident management with root cause analysis

- Corrective and Preventive Action (CAPA) tracking

- Competency-based employee training and certification tracking

- Inspection scheduling and reporting for assets and infrastructure

- Centralised complaint and feedback management

QMS software for oil and gas supports enterprise risk management by identifying operational hazards, logging near misses and incidents, and enabling timely mitigation actions.

It aids in managing high-risk scenarios such as equipment failure, non-compliance, and environmental spills through structured workflows and preventive measures aligned with HSE protocols.

Yes, QualityPro Oil and Gas QMS is fully customisable for various segments within the oil and gas value chain—whether it’s upstream (exploration and drilling), midstream (transport and storage), or downstream (refining and retail).

It accommodates specific functional requirements, including pipeline integrity monitoring, refinery quality assurance, and terminal operations compliance.

A QMS enables oil and gas organisations to track and manage their environmental impact effectively. It supports compliance with environmental laws, monitors emissions and waste management protocols, and ensures reporting in line with sustainability frameworks.

Absolutely. Cloud-based QMS for oil and gas companies provide secure, real-time access to quality data across remote and offshore assets. This facilitates collaborative decision-making, enables mobile audit and inspection capabilities, and supports scalability across multiple sites and joint ventures—all critical in geographically dispersed oil and gas operations.

QMS software streamlines core quality processes such as inspection reporting, equipment certification, and compliance documentation. By digitising manual workflows and integrating with enterprise asset management (EAM), it reduces human error, enhances inter-departmental collaboration, and boosts plant efficiency.

A QMS in oil and gas industry systematically records non-conformances, facilitates thorough investigations, and enforces corrective actions. It enables trend analysis and predictive reporting, helping prevent recurring issues and aligning operations with continuous improvement methodologies.

Oil and gas quality management software plays a critical role in Health, Safety, and Environment (HSE) compliance. It automates incident logging, hazard identification, and safety training tracking. This structured approach reduces the likelihood of workplace incidents, supports regulatory audits, and fosters a strong safety culture.

To deploy a quality management system software for oil and gas industry effectively, oil and gas firms should:

- Establish clear quality KPIs and regulatory benchmarks

- Digitise and standardise document control procedures

- Train the workforce on QMS tools and compliance requirements

- Continuously monitor quality metrics and leverage analytics for process optimisation and decision support

About Us

QualityPro is an eQMS software by TecWork Global Business Solutions, specially tailored for industries such as Electronics, Manufacturing, Electric Vehicles, Automotive, Food and Beverages, Solar panels, Pipe, Steel and more. TecWork Global Business Solutions, the parent company, endeavours to converge cutting-edge technology with business excellence. At TecWork, we are dedicated to empowering businesses through innovative solutions that specialise in and seamlessly align with diverse business objectives such as fleet management software, field force management software, and others.