Quality management in electronics manufacturing has become the cornerstone of success in an industry where a single defect can cascade into millions of losses. From smartphones to medical devices, electronic manufacturers face mounting pressure to deliver flawless products consistently.

The electronics sector operates within unique constraints – product lifecycles have compressed dramatically, yet quality expectations have only risen. This makes implementing robust quality control in electronics manufacturing not just beneficial, but essential for survival.

Looking for a digital solution? Explore our “QMS software for electronics industry“

This guide explores proven best practices that separate industry leaders from the rest, helping you build quality into your operational DNA.

Why Quality Management in Electronics Industry Matters More Than Ever

The Samsung Galaxy Note 7 crisis of 2016 serves as a stark reminder of quality’s importance. Battery defects led to a complete recall of 2.5 million devices, costing Samsung an estimated $5.3 billion in losses. But the brand damage proved even costlier – reputation built over decades suffered a blow requiring years to repair.

Samsung isn’t alone. Apple recalled MacBook Pro models for battery fire risks. HP has conducted multiple laptop battery recalls. These examples underscore a critical truth: in electronics manufacturing, quality isn’t a departmental function – it’s an organisational imperative.

What Are the Benefits of Quality Control in Electronics Manufacturing

When quality becomes non-negotiable, organisations experience transformative benefits beyond defect reduction.

Enhanced Customer Loyalty: Products that consistently perform as promised create emotional connections. When customers trust your brand will deliver quality, they become advocates rather than mere purchasers.

Operational Efficiency: Quality issues consume resources like slow leak drains in a reservoir. When defect rates drop, organisations redirect resources from firefighting to innovation. ZipDo industry research shows that the average defect rate in high-volume electronics manufacturing has decreased from 2% to 0.5% over the past decade due to quality improvements.

Cost Reduction: McKinsey research found that manufacturers implementing robust quality practices reduced their cost of non-quality – including warranty claims, waste, and rework—by approximately 30%. This includes reduced rework, fewer returns, and minimised warranty claims.

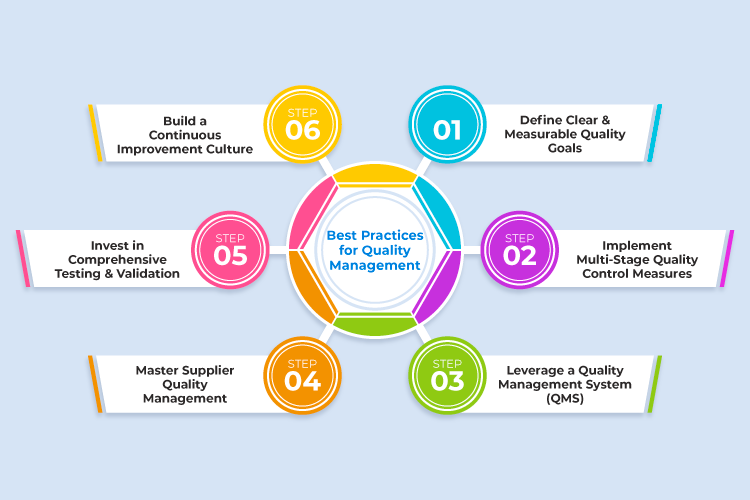

Essential Best Practices for Quality Management in Electronics Manufacturing

Achieving consistent quality in electronics manufacturing isn’t accidental – it’s engineered through deliberate practices and systems.

Define Clear and Measurable Quality Goals

Quality goals serve as your North Star for quality management in electronics industry. Effective goals are measurable, achievable, and aligned with customer expectations and regulatory requirements.

Start by understanding what quality means in your specific context. For consumer electronics manufacturers, a defect rate below 2% might represent excellence. For medical device manufacturers, the threshold might be 0.1% or lower.

Document these goals comprehensively, covering every production stage – from incoming material inspection through final product testing. This documentation should function as a living framework guiding daily decisions.

Practical Example: A circuit board assembly company establishes a goal of achieving zero solder defects in 98% of production runs. This specific, measurable target provides clarity and creates accountability.

Companies with clearly defined quality objectives demonstrate significantly higher customer satisfaction rates compared to those with vague quality aspirations.

Implement Multi-Stage Quality Control Measures

Quality control in electronics manufacturing resembles a safety net with multiple layers – each catching potential issues before they reach customers.

Incoming Material Inspection:

Your quality journey begins before manufacturing starts. Verify that components from suppliers meet specifications. A single batch of substandard resistors can compromise thousands of finished products.

In-Process Quality Checks:

Implement checkpoints throughout manufacturing where potential defects can be identified immediately. Automated optical inspection (AOI) systems detect solder defects and component placement errors at speeds human inspectors cannot match.

Final Product Testing:

Subject products to rigorous functional testing, environmental stress screening, and compliance verification before they leave your facility.

McKinsey research demonstrates that mid-level manufacturers reduced product deviations by more than 50% through systematic quality control measures.

Leverage a Quality Management System (QMS)

Managing quality through spreadsheets and disconnected systems is rather like navigating a modern city with a 1950s paper map – technically possible but unnecessarily difficult and error-prone.

A comprehensive Quality Management System provides the digital backbone for quality operations in electronics manufacturing. It centralises documentation, automates workflows, tracks non-conformances, and generates analytics for informed decision-making.

Key QMS capabilities should include:

- Document Control: Version-controlled access ensuring everyone works from latest information

- Non-Conformance Management: Systematic tracking preventing problems from slipping through cracks

- Compliance Management: Automated tracking for ISO 9001, IPC, and industry-specific regulations

See how QMS simplifies electronics compliance— “Request a Demo“

Master Supplier Quality Management

In electronics manufacturing, your quality is only as good as your weakest supplier. With complex products containing hundreds of components, supplier quality management becomes mission-critical for effective quality management in electronics industry.

Develop systematic approaches to supplier qualification and ongoing performance monitoring. Before onboarding suppliers, conduct thorough audits evaluating their quality systems, manufacturing capabilities, and compliance with relevant standards.

Implement supplier score carding tracking key performance indicators: on-time delivery, defect rates, responsiveness to quality issues, and specification compliance. Regular business reviews with strategic suppliers create forums for addressing concerns and driving improvement.

Practical Example: An electronics manufacturer sources display panels from three suppliers. By implementing score carding, they discover that Supplier B consistently delivers panels with significantly fewer defects despite higher unit costs. This data-driven insight allows strategic sourcing decisions optimising total cost of ownership rather than just purchase price.

Invest in Comprehensive Testing and Validation

Electronics products operate in diverse environments. Comprehensive testing ensures products perform reliably across conditions rather than just in controlled settings.

Develop test plans addressing:

Functional Testing:

Verify products perform intended functions according to specifications using automated test equipment (ATE) executing thousands of test points in minutes.

Environmental Stress Testing:

Subject products to temperature extremes, humidity, vibration, and other real-world factors. Accelerated life testing predicts long-term reliability from short-duration tests.

Safety and EMC Testing:

Ensure products meet regulatory compliance and protect end-users from hazards whilst preventing electromagnetic interference.

ZipDo research tells that manufacturers incorporating comprehensive testing protocols during product development reduced average defect rate from 2% to 0.5% over past decade in high-volume electronics manufacturing

Build a Continuous Improvement Culture

The most sophisticated quality systems fail when employees view quality as someone else’s responsibility. Building a culture where everyone owns quality transforms it from a departmental function to an organisational characteristic.

Leadership sets the tone for quality management in electronics manufacturing. When executives prioritise quality in resource allocation and performance metrics, the organisation follows.

Establish regular system for process evaluation. Monthly or quarterly reviews where cross-functional teams analyse quality metrics, keep quality front and centre. When issues arise, conduct root cause analysis using methodologies like the 5 Whys to address underlying causes rather than symptoms.

Empower employees to stop production when they identify quality issues. A production line stopped for 30 minutes to address a defect beats shipping thousands of defective products to customers.

Taking the Next Step in Electronics Quality Management

Implementing these best practices isn’t a one-time project – it’s an ongoing journey of organisational transformation. Start by assessing your current state honestly. Where do gaps exist between your current practices and industry best practices?

Prioritise initiatives based on impact and feasibility. Quick wins build momentum and demonstrate value. A phased implementation approach allows learning and adjustment rather than attempting wholesale change overnight.

The electronics market will continue evolving at a dizzying pace. Through it all, one constant remains: quality wins. Organisations recognising quality as strategic investment rather than cost obligation will thrive.

For electronics manufacturers seeking to implement these practices systematically, comprehensive QMS solutions provide the framework and tools to transform quality aspirations into operational reality.

QualityPro by TecWork offers a scalable eQMS software specifically designed for electronics manufacturing complexities – supporting your quality excellence journey through thoughtful alignment with how manufacturers actually work.

The question isn’t whether you can afford to implement robust quality control in electronics manufacturing. The question is whether you can afford it not to.

Looking to improve quality practices in electronics manufacturing? “Contact Us“

Frequently Asked Questions

QualityPro helps build a culture of continuous learning by offering comprehensive training module. The module ensures that all employees are aligned with quality standards and best practices. By providing role-specific training, it empowers employees to recognise quality issues early and take appropriate action, such as halting production if needed. The system’s real-time alerts and reporting further support quick decision-making and continuous improvement in quality management.

QualityPro embeds continuous improvement into the fabric of your quality management system by providing tools for regular process evaluations, root cause analysis, and performance tracking. It uses analytics to track quality metrics across production stages, helping you identify trends and areas for improvement.

With automated corrective and preventive action (CAPA) workflows, QualityPro ensures that any issues identified are addressed in a timely and systematic manner, driving long-term quality improvement.

It simplifies compliance management by centralising documentation and automating workflows to ensure compliance with industry standards such as ISO 9001 and IPC. The system tracks non-conformances, manages audits, and ensures that your operations are always up to date with the latest regulatory requirements.

By automating compliance tasks, the software reduces the risk of human error and helps maintain certifications with minimal effort, ensuring that your products meet all safety and regulatory standards before they reach the market.

Data analytics plays a crucial role in identifying patterns and anomalies in the manufacturing process. By analysing production data in real-time, manufacturers can quickly pinpoint areas where defects are occurring and implement corrective measures before the issue escalates.

Analytics can also predict potential failure points, allowing for proactive maintenance and reducing downtime. Over time, this leads to improved product consistency, fewer defects, and reduced waste in high-volume production environments.

As the electronics industry grows and new technologies emerge, regulatory standards continue to evolve. Staying compliant with these changing regulations is critical to ensuring that products meet safety, environmental, and performance criteria.

For manufacturers, this means continuously adapting their quality management systems to meet new requirements, whether it’s for environmental impact, product safety, or electromagnetic compatibility (EMC). Effective quality control systems help manufacturers stay ahead of regulatory changes, ensuring that they avoid costly recalls and penalties.