The Role of Change Management Software in Automobile Manufacturing

Change is inevitable. Even the Bhagavad Gita (an ancient book) teaches us the same too. It says, nothing in life is permanent except the change itself. To resist it is to resist life. To accept it is to evolve. This lesson is well-suited for the automobile industry.

The automotive industry is accelerating towards a future defined by innovation. But with every new development or change, complexity increases—raising the risks for manufacturers to meet the highest standards of safety, quality, and compliance.

Here, even a tiny change— like switching to a new brake pad vendor, adjusting engine calibration settings, or modifying the paint curing temperature—can create chaos. One small shift can lead to confusion on the shop floor, delays in production, or issues with compliance or quality, if not handled properly.

In fact, the research shows that almost 70% of change initiatives fail—often due to poor planning, lack of communication, and ineffective tracking—which can lead to costly errors or product recalls. (Source: https://pubmed.ncbi.nlm.nih.gov)

Read this blog to explore why change management is essential, why it cannot be ignored, and why it is essential to have a robust Automotive QMS (Quality Management System) to manage change.

What Is Change Management? And How It Impacts the Automobile Industry?

Change management means handling any updates or changes in a planned and organised way. In the automobile industry, where things like new parts, updated models, or process changes happen often, managing change properly is very important.

If not handled well, even a small change can cause delays, errors, or quality issues. That’s why auto manufacturers need a clear system to track, review, and approve changes smoothly and safely.

The Changing Landscape of the Automobile Industry

Be it the launch of new technologies or constantly changing emission norms, the automobile industry is changing more than any other industry. Recent changes in this industry include:

- Electric Vehicles (EVs) – The launch of battery-driven EVs has been the biggest change the automotive industry has seen since the days of launch of the Internal Combustion engine.

- Autonomous Technology – More and more cars, be it the ICEs or the new EVs, are now coming with AI and sensor-based technologies.

- Connected Cars – Most cars today can communicate with other devices, have Alexa and Google built in, and communicate with other cars as well as with the cloud.

- Digital Manufacturing – Most auto manufacturers now have smart factories powered by a lot of automation, data, and real-time analytics.

With more and more changes coming in and regular innovations & ideas pushing manufacturing boundaries, automakers are under a lot of pressure to adapt to changes while maintaining and exceeding the highest levels of quality, compliance, and traceability.

Why Change Management Is Non-Negotiable?

Automobile manufacturing and automobile component manufacturing are not just about assembling parts; there is a whole lot more to it. It is all about achieving precision, ensuring safety, and meeting global compliance standards such as IATF 16949, ISO 9001, ISO 26262, ASPICE, and others that have set a high bar for quality and safety. Managing changes manually or without a change management software for automobile industry can lead to a host of risks, including:

Regulatory Non-Compliance –

Without a proper change management system in place, manufacturers risk implementing changes that don’t meet regulatory standards. This not only leads to compliance failures but can also result in heavy penalties, legal action, and even production shutdowns.

Uncontrolled Revisions –

When design or process changes are made without a structured system, it often leads to confusion on the shop floor. Unclear instructions, miscommunication, and overlapping revisions can cause production errors, rework, and increased costs.

Lack of Traceability –

Manufacturers implementing changes manually or without a digital trail struggle to trace who made what change, when, and why. This lack of visibility complicates audits, hinders root-cause analysis, and makes product recalls slow and chaotic.

Quality and Safety Risks –

Changes that are not properly documented, reviewed, or validated can compromise the quality and safety of the final product. This increases the chances of defects, recalls, and customer dissatisfaction—ultimately putting the brand’s reputation at risk.

Miscommunication –

Automobile manufacturers that do not have a good change management system frequently find themselves doing duplicate work due to the lack of effective communication, having manufacturing delays, inefficient production, and safety concerns in their products.

In short, poor change management can not only compromise product quality but will also end up harming customer trust, business reputation, and repeat business. Hence, change management in the automotive industry is a must-have.

How to Manage Change in Automotive Manufacturing?

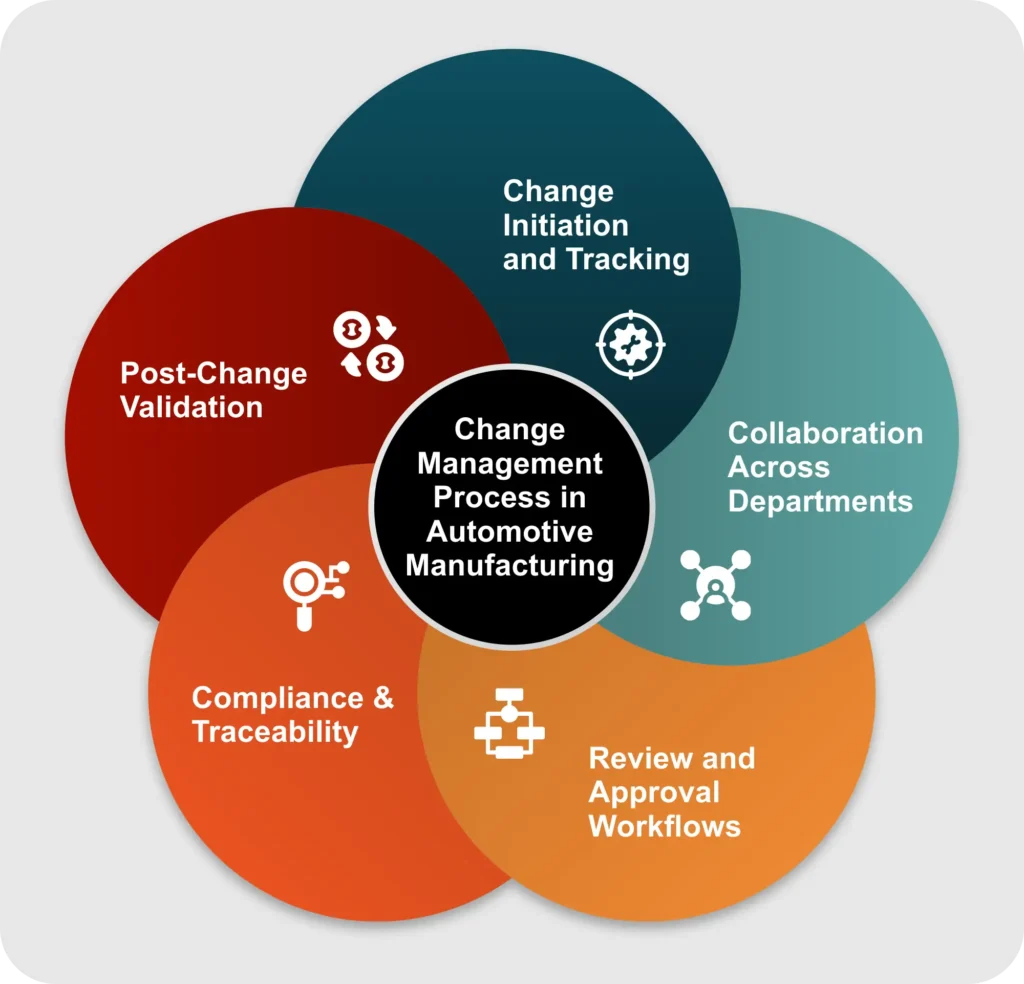

As said, change management with trackability and traceability is extremely essential for any and every automobile manufacturer today. This is where a robust Quality Management System (QMS) like QualityPro plays a critical role. It acts as a centralised, automated, and traceable platform that enables manufacturers to effectively manage and implement changes across the organisation by facilitating:

- Change Initiation and Tracking – Whether it’s updating a brake assembly design, switching to a new alloy for engine parts, or modifying assembly line torque settings, every change can be logged and tracked with full transparency.

This includes maintaining detailed records of who initiated the change, when it was approved, and its current status—ensuring visibility and accountability at every step.

- Collaboration Across Departments – From R&D teams in the USA suggesting an ECU firmware upgrade to plant engineers in India implementing it, QualityPro’s shared dashboards and real-time notifications help break silos. Everyone works on the same version of the change record. So, no more scattered spreadsheets or outdated emails.

- Review and Approval Workflows – Whether it’s a safety-critical part substitution or a

supplier-initiated material change, QMS software automates the approval cycle. It routes requests to the right stakeholders, sends alerts, and ensures only authorized personnel review and greenlight changes—minimizing bottlenecks and errors.

- Compliance & Traceability – All changes, say, adapting to any emission norms or meeting OEM-specific tolerances, are audit-ready. QMS solutions track every revision, from initiation to closure, maintaining a digital trail to ensure compliance with standards like IATF 16949, ISO 9001, and OEM-specific requirements.

- Post-Change Validation – Before rolling out a new change, let’s say, new seat belt anchoring process or changing a supplier’s raw material spec, QualityPro mandates structured validation. Only when validated, the change is fully deployed, ensuring no compromise on quality or safety. This change is visible to every single authorised person.

How QualityPro Empowers Automobile Manufacturers to Own the Change?

QualityPro, an Automotive Change Management Software helps automobile manufacturers with:

Centralised Control over Every Change

With QualityPro, change is no longer a scattered, paper-based mess. You can:

- Initiate and document change requests—define the source, category, and reason for the change.

- Plan and implement seamlessly—track execution steps and affected departments in real-time.

- Digitise everything—replace error-prone manual tracking with a streamlined, automated system.

- Estimate costs and resources—evaluate the financial impact before rolling out a change.

- Prepare your people—identify employees needing training and schedule it accordingly.

Bring Traceability and Accountability to Life

- Every detail matters—and QualityPro tracks it all:

- Know who changed what, when, and why—with complete version history and change logs.

- Establish procedural workflows—control access, assign responsibilities, and enforce approvals.

- Manage lifecycle of every change—from request to execution to closure, with full documentation.

- Generate and share key metrics—change versions, training logs, source of change, and more, all available at your fingertips.

Ensure Compliance at Every Step

- Stay ahead of audits, recalls, and regulatory mandates:

- Systematically store and manage all documents—organised, accessible, and always up to date.

- Maintain a full audit trail—record every step of the change process to prove compliance.

- Validate and approve changes—before they go live, not after issues arise.

- Purge outdated versions—ensure only current, approved documents are in use across the organisation.

Key Benefits of Change Management Software for Automobile Manufacturers

QualityPro by TecWork is a next-gen QMS with powerful built-in change management in the automotive industry. It centralises all change control needs while ensuring compliance, efficiency, and full traceability.

- Industry-Specific – Tailored to meet the unique needs of automotive production lines, parts suppliers, and OEMs.

- Seamless Change Control – Track and manage Engineering Change Requests (ECRs), supplier changes, and process updates from initiation to closure.

- Automated Workflows – Ensure timely approvals and eliminate bottlenecks with rule-based workflows and smart notifications.

- Comprehensive Compliance – Aligns with global automotive regulations, offering built-in tools to support compliance documentation and audits.

- Enhanced Supply Chain Visibility – Keep suppliers and teams informed through integrated communication and real-time status tracking.

- User-Friendly Interface – Intuitive and accessible for all departments, driving faster adoption and better efficiency.

- From process upgrades to regulatory shifts—QualityPro ensures change management runs smoothly and effortlessly.

Concluding Thoughts

As an automobile manufacturer, staying ahead means handling constant upgrades, complex supply chains, and strict audits. A unified QMS like QualityPro with built-in change management can transform how you operate.

But it doesn’t stop there—QualityPro also offers modules like Document Control, CAPA, NC Tracking, Audits, Training, and more to help you maintain top-tier quality, safety, and compliance.